Milwaukee’s Michigan Street Lift Bridge

October 9, 2020

Yes, You Should Consider a Custom Hydraulic Manifold. Here’s Why

July 27, 2023

Milwaukee, Wisconsin has more movable bridges than any U.S. city besides Chicago. Milwaukee’s three rivers are major waterways for boats coming to and from Lake Michigan. River traffic in the city has the right of way, so many bridges must be able to move out of the way for boats. In 2021, the city recorded over 27,000 bridge openings across its 21 movable bridges. One bridge can open up to 50 times on a busy Saturday during the summer.

The Michigan Street bridge, one of the city’s eight vertical lift bridges, was scheduled for rehabilitation in October of 2019. The project would upgrade and replace the existing structural, electrical, hydraulic, and mechanical components, the bridge house, and the roadway approach. MFP Automation Engineering was a key subcontractor for this hydraulic lift bridge project.

Turnkey Solution and Design Modifications

As part of our bid for the project, we offered to handle more of the system than just the hydraulics. We also quoted assisting with the initial demolition, installing over a thousand feet of stainless steel tubing, and supplying and assembling the structural steel to support the hydraulic cylinders.

During the planning phase, we suggested a few design modifications to help minimize leaks, save space, and ensure the bridge performed to the city’s specifications. Our modifications included changes to the hydraulic manifold, control system, and proportional valves.

Cold Weather, Tight Timeline, and Supply Chain Disruptions

Of course, no project is without its challenges. Most of the work was scheduled for November 2019 through March 2020. Repairing bridges during the winter months is fairly common for cities like Milwaukee that get an influx of tourists during the summer. Tearing down a bridge and rebuilding it in the winter is less disruptive to traffic flow and doesn’t cause as many complications during the busy tourist season. However, that meant our installers had to coordinate around unpredictable winter weather and work out in the open on 20-degree days.

The project was on a tight schedule. One of the main concerns was the Democratic National Convention scheduled to come to Milwaukee in August 2020. The city was expecting more visitors than usual, and the Michigan Street bridge was one of the main ways people would get from their hotels to the west side of town.

And, like everyone else in 2020, we were affected by supply chain disruptions. Many of the hydraulic components we needed were delayed by several months.

Bringing Everything Together

Despite the challenges, it was exciting to see the project come together over the next few months.

Cylinder Mounts

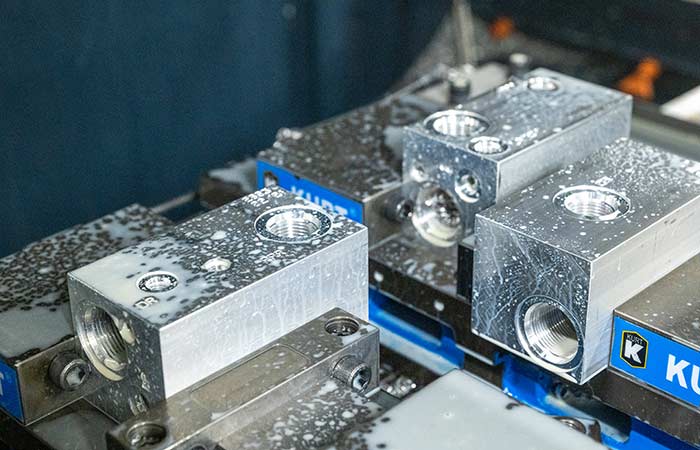

For the hydraulic cylinders, we built assemblies for the gimbal mounts and all of the structural steel and special bronze bushings which supported the lift cylinders. The gimbal mounts allow the cylinders to pivot 360 degrees in any orientation and help to keep the bridge steady as it lifts.

65 Foot Pipe

A unique feature of the design was the single hydraulic system on one side of the bridge. The engineering firm did this to consolidate components and avoid having a system on each side of the bridge.

Our challenge was to get hydraulic fluid up over the bridge and back down without it being an eyesore. We decided to use a 65-foot pipe and have the entire length welded in Michigan. The pipe was too long to ship on a standard truck, but we opted for this approach, so we had full control on the cleaning and rigorous leak testing and make sure the pipe was up to our standards.

Operating Sequence

We also designed and programmed the operating sequence. Everything had to be extremely precise to keep the bridge as flat as possible while it was in the air. Milwaukee deals with unpredictable weather and a spring snowstorm could leave more snow on one side of the bridge than the other. It was critical for the bridge to handle a potential load imbalance and keep everything level.

Each of the four hydraulic cylinders included a sensor to help monitor and adjust how fast it went up or down. If one corner was moving faster or slower than the others, the system made adjustments to the speed so it kept pace with the other corners. So many small details go into lifting 1.5 million pounds of steel and concrete into the air. Our operating sequence had to be perfect.

The specifications called for extremely tight tolerances within half an inch over the 40-foot span of the bridge. We decided to test the system by putting a pickup truck loaded with tools and equipment on one end of the bridge. Everything worked beautifully and the bridge stayed level, despite the extra 10,000 pounds or so on one side!

A Team Effort

Milwaukee’s Michigan Street lift bridge reopened for vehicular traffic on Friday, July 31, 2020, just in time for the Democratic National Convention in August.

It takes a team effort to make a project like this a success and MFP was excited to lend our expertise. The bridge will be a beautiful and functional part of Milwaukee’s infrastructure for years to come!